- Via Emilio Ciocca 24/26 - Codogno (LO)

- info@inveniosolutions.it

Home » Electrospinning

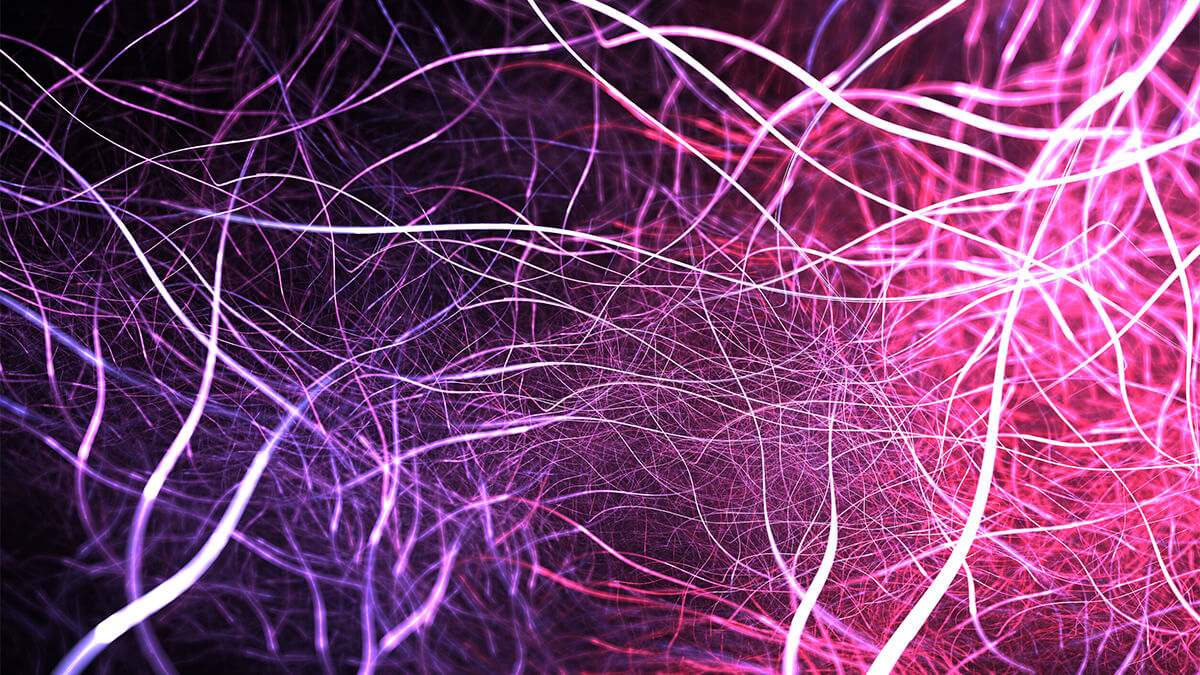

Electrospinning is a process that allows the fabrication of nanometre-diameter fibers (so-called nanofiber) from polymer solutions. The fibers are formed by evaporating the solvent while thesolution is passing through a high electric field.

The first patent related to this methodology dates back to 1902 by J.F. Cooley and W.J. Morton, who devised a process to disperse fluids through an intense electric field.

Electrospinning allows nanofibres to be obtained from both natural and synthetic polymers. The solution in which the polymer has been dissolved is loaded into a syringe with a needle, called a spinneret, and then extruded through it at a constant flow rate by a pump. An electric field is applied between the spinneret and the collector, that is, the component in which the nanofibres are deposited: both components are therefore electrically charged.

As the solution begins to flow out of the needle, applying a high-voltage electric field induces a droplet deformation in the so-called “Taylor cone” formation. At the tip of the cone, the droplet emits a jetthat rapidly stretches, elongating and thinning itself. The free electrical charges in the starting solution interact with the applied electric field. The potential difference between the solution in the spinneret and the manifold induces the formation of the jets.

The latter are directed from the spinneret to the collector at the same time as the solvent is evaporating. By the time the jets reach the grounded collector, discharging electricity, the solvent has now evaporated and dry, solid fibers are visible.

Needle-free Electrospinning enables the production of nanofibers starting from the liquid surface of a polymersolution.

The first setup for this type of electrospinning was developed in 1979 by Simm et al. while, in 2005, Jirskar et al. filed the first patent for an NLES setup, which was commercialized the following year by the Czech company ELMARCO under the name Nanospider®.

In this case, the spinneret consists of a rotating cylinder partially immersed in the polymer solution. During rotation, a thin layer of solution is formed on the cylinder, thus allowing for the formation of the jets.

Invenio has chosen to use precisely the needle-free Electrospinning technology to produce Neatess®

Fill out the form to receive more information about Invenio

2021 © Invenio Srl | Via Emilio Ciocca 24/26 – Codogno (LO), Italy – VAT No. 11306580967 | info@inveniosolutions.it |

Privacy Policy |

Cookie policy |

Design by A2 Lab

2021 © Invenio Srl | Via Emilio Ciocca 24/26 – Codogno (LO), Italy – VAT No. 11306580967 | info@inveniosolutions.it |

Privacy Policy |

Cookie policy |

Design by A2 Lab

2021 © Invenio Srl

Via Emilio Ciocca 24/26 – Codogno (LO), Italy

VAT No. 1130650967 | info@inveniosolutions.it

Privacy Policy

Design by A2 Lab

2021 © Invenio Srl

Via Emilio Ciocca 24/26 – Codogno (LO), Italy

VAT No. 1130650967 | info@inveniosolutions.it

Privacy Policy | Cookie Policy

Design by A2 Lab